ACE Manufacturing Co. is premier plastic mold Manufacturers in Pune, renowned for delivering high-quality and precise plastic molds. Our expertise covers a wide range of molds, including Injection Moulding molds and Plastic Bobbin Molding molds. We pride ourselves on catering to diverse industry needs with consistent excellence.

Our product lineup includes customized white round plastic molds, specifically designed to meet unique production requirements. Each mold is crafted with precision to ensure durability and long-term performance. This customization allows manufacturers to achieve exact specifications for their plastic components.

Designers and manufacturers who prioritize accuracy and longevity in their plastic molds rely heavily on our products. Our molds enhance production efficiency and maintain consistent quality throughout their lifecycle. We are committed to supporting the success of plastic component production with reliable, superior molds.

Why Choose us for Plastic Mould in Pune?

We are reputed Plastic Mould Suppliers in Pun that guarantee precision and effectiveness as we provide tools that will always give quality plastic parts with precise dimensions that protect against scrap and re-work. We have Plastic Bucket Mould and Battery Case Plastic Mould.

Our Plastic Moulds give a visible, tangible guarantee of accurate and repeatable production of plastic parts, enabling work without dimensional inaccuracies or waste of material. This guarantees security in the plastic manufacturing industry

Types of Plastic Moulds

There are different types as per maintenance and equipment’s requirement modified which are given below:

- Two-plate Moulds: They are the most widespread and the easiest type of mould, having two plates with the halves of the cavity and the core splitting to release the molded component. They suited simple components without undercuts.

- Three-Plate Moulds: These moulds have three plates and the automatic degating of the runner system is possible. They suit portions that require intricate gating.

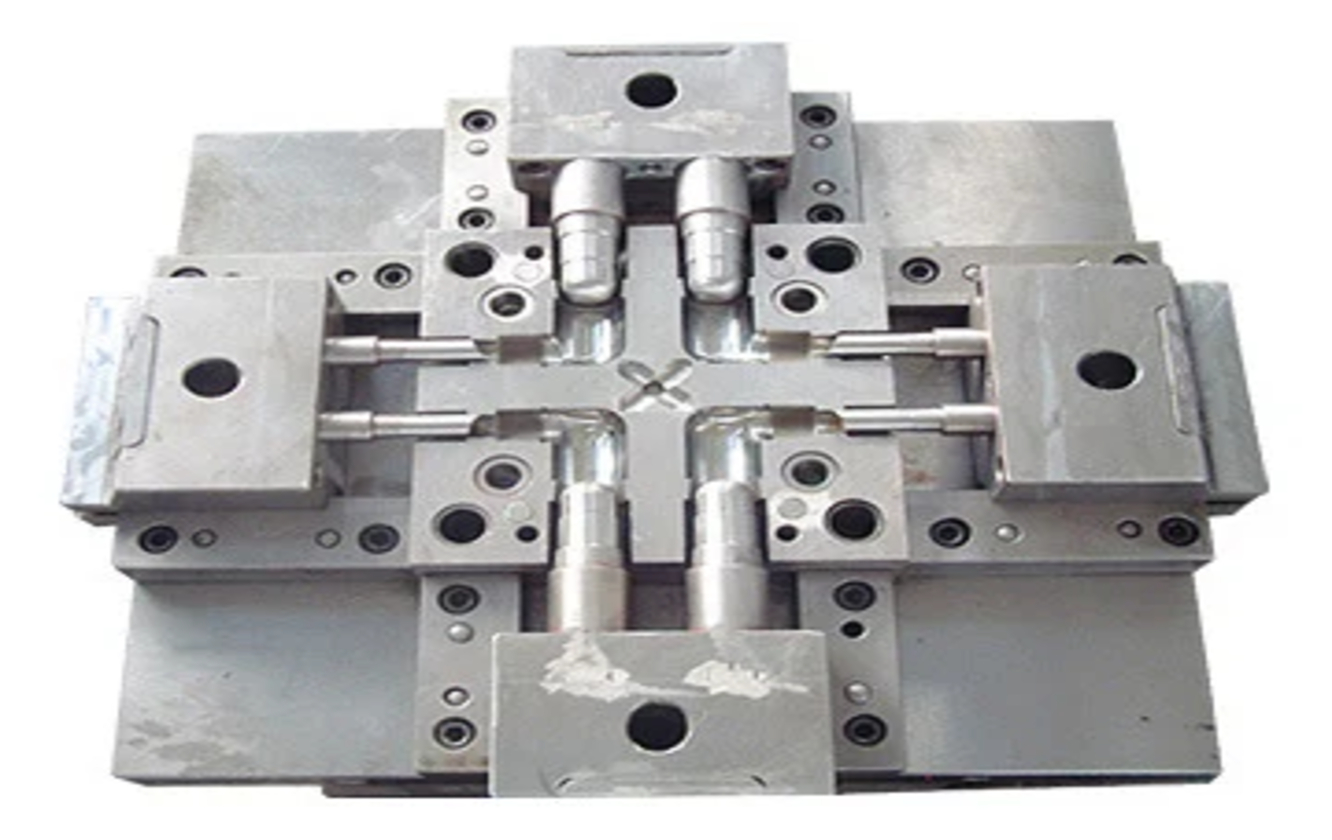

- Split-Cavity Moulds: These moulds, used when the part has an undercut or otherwise complicated external shape, have movable slides or inserts. The slides have to be retracted prior to ejection to remove parts.

- Hot Runner Moulds: These moulds maintain plastic in a heated manifold, and inject it directly into cavities molten. This gets rid of runner waste and shortens cycle times.

- Side Core/Side Cavity Moulds: These moulds have movable pins or slide and are designed to produce parts which have internal or external undercuts. These features are withdrawn to eject parts.

Technical Features

We have added below a technical sheet of Plastic Moulds that provides more technical information such as:

| Features |

Description |

| High Accuracy and Consistency |

Manufactures parts with unbelievably low dimensional tolerance, and high uniformity of quality. |

| Cost effective Mass Production |

Enables economies of scale of productive output cost. |

| Versatility in Design |

Allows having complex and intricate geometries to be made. |

| Excellent Surface Finish |

Moulded parts come out with a smooth, cosmetic surface finish often needing no further post-processing. |

| Reduced Material Waste |

Errors which result in less scrap and wastages of materials are obtained through proper molding. |

Benefits of Plastic Mould:

The different benefits are served as per system need and different potential level which are given below:

- High accuracy and consistency: Plastic moulds provide components with exceedingly tight dimensional tolerance and consistent quality which is mandatory in mass production.

- Cost effective Mass Production: They allow efficient high-volume production of plastic parts, which lowers the cost of producing a unit part considerably.

- Versatility in Design: Elaborate and complicated geometries can be created using plastic moulds, thus enabling highly diverse product shapes and capabilities.

- Excellent Surface Finish: Moulded parts also tend to come out with a nice smooth cosmetic surface finish that may need no further post-processing.

- Reduced Material Waste: Accuracy of the molding processes results in less scraps or material wastage which makes the productions more sustainable and cost effective.

Applications of Plastic Mould:

Here are mention some applications of our Plastic Mould:

- Household Goods: Moulds that are made of plastic are used in the making of various products such as containers, appliances and furniture. These facilitate the production of mass consumption items of daily household use in a cost-effective way.

- Automotive: Required in the production of complex automobile parts, allowing light-weight constructions.

- Electronics: Vital in designing housing and parts of small devices that are functional.

- Medical: Essential in the production of sterile and highly accuracy medical devices and surgical components.

- Construction: Applied to long-lasting and weather-proof construction components such as pipes and window profiles.

The ACE Manufacturing Co. is one of the best Plastic Mould manufacturers, suppliers in Pune. We have reliable procedures that make sure that all the Plastic Mould in Pune exceeds the performance and safety standards.

We are trusted Plastic Mould Suppliers in Pune. We are making high grade, superior Plastic Moulds, such as Plastic Molds for Injection Moulding, Hot Runner Molds, Two-Plate Molds, and Split-Cavity Molds, Household Goods, Automotive, Electronics, Medical, and Construction. This has given us a steady reputation of efficient plastic component manufacturing in India.